Brunel Swivel Bridge Project 2013

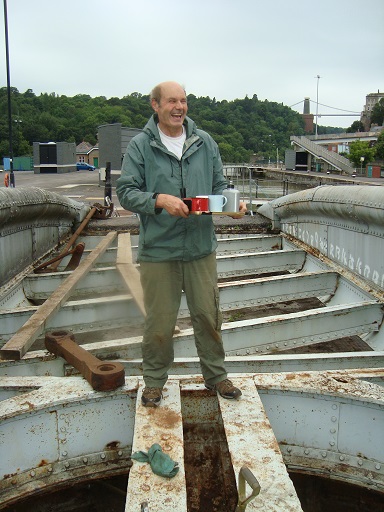

Geoff Wallis with wheel

Page contents

Funding

On the 4th and 6 May a group of people from the Swivel Bridge Group, in coordination with the Bristol Industrial Archaeological Society, the Avon Industrial Buildings Trust and Clifton and Hotwells Improvement Society organised a working party, and funds, to slow the deterioration of the bridge, improve its neglected appearance and raise its profile.Clifton and Hotwells Improvement Society, Bristol Industrial Archaeolgical Society and Avon Industrial Buildings Trust each put forward £1000 to fund tools and start investigation using volunteers.

Work PHASE A Preparation and Basic Conservation by Volunteers

May 2013: Draft Schedule of Work to improve the site's neglected appearance- Locate and obtain copies of drawings and past reports

- Provide temporary barriers at both ends of the structure to prevent access between the Bridge and basin

- Lay temporary boarding along the west end of the deck to provide access

- Clear debris, vegetation, etc, from around and under the Bridge, and in the hydraulic jigger-pits. Dispose off site

- Scrape/chip off loose rust, apply temporary coating of rust inhibitor

- Free-off the shackle-pins on the steel rope and remove if accessible

- Provide a 2 inch (51mm) spanner/socket, free off and remove 8 pairs of nuts securing the four support-wheel bearing caps. Lift off caps, clean, inspect, record, lubricate and reassemble.

- Provide a spanner/socket, free off and remove 4 pairs of nuts securing the two tail wheel bearing caps. Support the wheels, lift off the caps, clean, inspect, record, lubricate and reassemble.

- Remove deck boards to store on site, and dispose of rubbish, leave the site tidy

Progress

September 2013

Putting the signs up certainly raised the profile and we had lots of visitors including two from English Heritage who happened to be passing, and Charlie aged 10 who had been on the Gromit trail ended up helping us all day instead. All the wheel bearings cleaned now. We have also been looking at the skill of the riveter and doing some research.7 September:

- Volunteers continued to excavate the four support wheels and generally clean round them, excavated and cleaned the track under the tail of the Bridge, and took off the tail-wheel bearing caps and serviced the bearings.

- We put penetrating fluid on the central spigot and wire rope connectors.

- We could not get any more wheels to turn since the central rim was resting on the wheels.

- We also put signs up (using existing holes) on either side of the bridge to lift the profile.

Signs to promote the bridge stand out well. |

Geoff has every reason to look really happy! |

Geoff and Mary Stacey of AIBT discussing matters. |

Charlie helping Geoff grease the bearings |

Mike Bone and Mary Stacey digging out the wheel pits as far as possible. |

Geoff showing Charlie the different kinds of jack |

Michael discussing the work in progress with Charlie |

Different style of bearing |

Geoff removing bearing from north tail wheel, and Michael from the south tail wheel with Charlie looking on |

Charlie posing by by a whhel having helped dig out the wheel pit |

Mike and Michael putting up the sign on the North side with Geoff and Mary discussing above |

Mike and Michael putting up the sign on the South side with Geoff and a visitor discussing above |

August

Another satisfying weekend. 4 more bearings cleaned and lots of rust to worry about. We put some paint on a trial part. All 8 bearings (2 per wheel) have been cleaned and greased now, and we even got a wheel to turn!We were even treated to looking at the chains that pulled the bridge open during our tea break.

BIAS funded air chisels, tarpaulin, ear defenders, safety goggles

24, 25 August 2013:

- Volunteers lifted the caps of the remaining wheel bearings which were found to be in good condition.

- Some paint was applied to inside one of the struts in a test area to see how effective it would be.

- Some of the wheel pits were cleared of dirt and a wheel was made to turn.

- We were concerned about the rust flakes as we cleaned bridge beams.

Everyone is happy. This is Dave |

Graham |

Mike |

Maggie |

Test paint |

Mike applying the paint |

Wheel pit |

Graham demonstrating the wheel turning easily |

Not much space on outer bearings |

Clean bearing in good condition |

Graham greasing the bearing and studs before cap put on |

Graham and Geoff getting the wheel to turn |

another bearing to move. We cleaned two today- only two more to go |

bearing- tight space, big nut |

needs two to lift the bearing off |

bearing needs cleaning |

Chains still there |

Chains along the dockside |

Chain wheels |

Connecting cogs |

bucket of rust flakes |

rust on the turning section |

Geoff finding more rust flakes to put in his bucket |

rust on the girder section |

June

One wet day organised to improve the neglected appearance by volunteers15 June 2013:

- Volunteers on a wet day tried out an air chisel to see how effective it would be on cleaning off loose rust on the struts

getting stuck in tight spaces again |

Maggie using an air chisel to clean off heavy flakes |

getting very wet |

building a shelter |

May

Two days organised to improve the neglected appearance by volunteers. CHIS funded paint brushes, scrapers, gloves4, 6 May 2013:

- Volunteers from CHIS, AIBT, BIAS, Hotwells and Cliftonwood, Clifton Rocks Railway filled a skip on a bank holiday weekend with the contents of an inspection pit, general dirt from the bridge particularly in the main struts, and weeds from the area.

- Four wheel bearings had the caps lifted, cleaned, checked and regreased before replacing. They had an unusual tapered design.

- Started to clear some of the wheel pits of dirt.

Mike Bone chairman of BIAS, cleaning the girders |

Geoff Wallis of Dorothea and BIAS looking pretty pleased with the progress |

Ray from Hotwells, Geoff and Dave cleaning the girders |

Mike cleaning the rail |

Mike from BIAS down a hole, with Dave standing by |

Geoff wondering if his spanner will fit the nut |

cleaning in a restricted place |

rope connecting the wheels |

the struts needed cleaning to drain the water awy |

the bridge is only supported by the main pivot |

Geoff and Stefan from CHIS inspecting a bearing |

Dave and Maggie from CHIS and BIAS wondering if she would be able to get out |

- March 2013: The Swivel Bridge Group in coordination with the Bristol Industrial Archaeological Society and the Avon Industrial Buildings Trust and CHIS organise a working party and funds to slow the deterioration of the Bridge, improve its neglected appearance and raise its profile. Support by the Dockmaster given for the first stage. Contact Maggie Shapland for more details

Brunel's Other Bridge

Brunel's Other Bridge