Brunel Swivel Bridge Project Photos April 2016

Page contents

Investigative Work in 2016

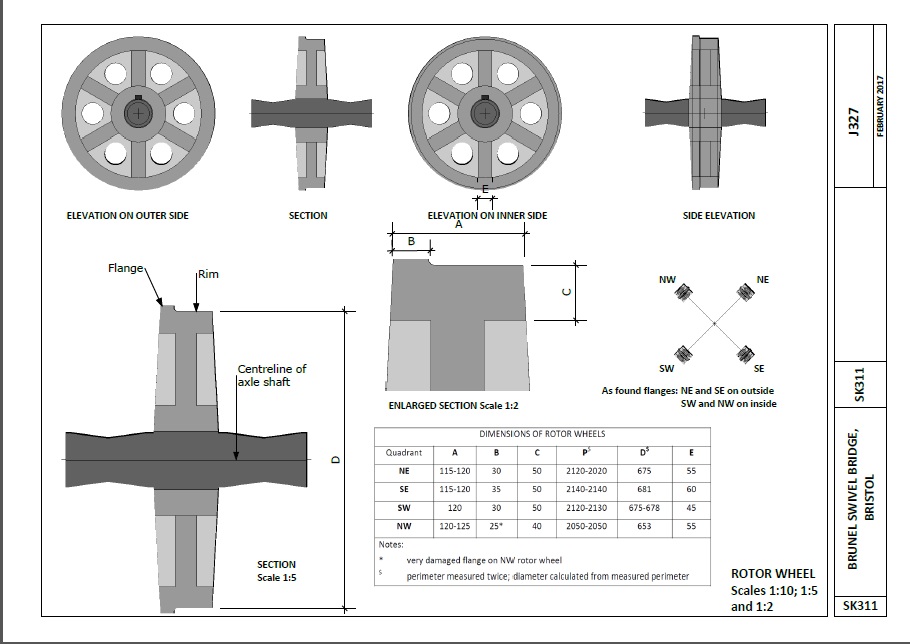

turntable rotor wheel dimensions

April 2016

It is reassuring to see the relatively good condition of the tie-rods and cast iron end fittings, and if they are all like this we probably will be able to extract one or more wedge and re-tension the tie-rod on the south side. It appears from these that at least the end tie is in fair condition as is the internal surface of the iron – as far as we can see. The photo near the pintle support appears to show that we have one quite thick tie and a second thinner tie immediately alongside it. This probably corresponds in sectional area to three of the single ties.The diameter of the turntable rotor wheels was calculated from the dimension around the perimeter, measured a couple of times with a thin flexible wire wrapped around the circumference of the rim.

looking at the end of the last tie near the cantilever end of the bridge |

end of the last tie near the cantilever end of the bridge |

shows the condition of the internal surface nearby |

looking up at the ties near the pintle support |

Bob working with new volunteer Victoria a civil engineer student from UWE measuring the turntable rotor wheels |

Bob and Victoria looking at the tie rods |

Timber Stop (involved more and more people as the day progressed)

We came to add the support to the stop Graham had made in 2015 |

to our surprise on digging the hole for the support we found a stud with a nut and washer that undid easily |

new volunteer David finding bits of clay pipe and Reece using the post hole digger |

Mike, Ian and Geoff lifted out Graham's stop |

Geoff making adjustments, the new support standing by |

Mike, Ian, Geoff, David, Bob, Martyn and Reece all needed to lump these heavy baulks of timber around |

trying to install the support |

deep thought |

Geoff gets out his trusty drill so the support can go back on the original stud, being very precise with the level |

Bob uses the chisel to make a square hole on the support |

ready to put back in the hole |

will need further mods in May! |

Clear rust from inside holes where plates have been removed

Sal using a telescopic back scratcher to reach into the the corners |

Martyn using a wire brush |

many beams to clean |

Ian grinding the turntable |

February's excavations had left the path by needing improvement |

Martyn, Mike and Sal smoothed the ground and used a tamper |

This time it was Sal doing the work and Martin and Mike watching |

tarmac laid down |

one of the wheel pit drain holes was blocked. There was not much room to get under the wheel so the trusty back scratcher came in useful to clear out leaves and sediment |

The wheel area was swept clear of all the rusty flakes and debris |

Brunel's Other Bridge

Brunel's Other Bridge