Brunel Swivel Bridge Project

Brunel Swivel Bridge, with the Suspension Bridge in the background |

Details of the following will be found below:

- Aims

- Conservation Policy

- The Whole Plan

- Donations

- Progress to date

- CONTRACT WORK undertaken up to March 2016:

- Work PHASE B 2015 Preparation and Basic Conservation by Volunteers

- Work for 2014 Preparation and Basic Conservation by Volunteers

- Work PHASE A 2013 Preparation and Basic Conservation by Volunteers

Aims

The project aim is to conserve BoB in situ as an historic monument, but in working condition to allow occasional use by pedestrians and cyclists as an alternative means of crossing the North Entrance Lock.The bridge stands on the harbour side alongside a popular walking and cycling route, whilst those afloat see it whenever they pass through the lock. Often seen as “just a rusty bridge” the project intends to re-establish BOB’s status as an important and iconic Brunel Bridge. We wish to:

- To improve the site’s neglected appearance

- To slow deterioration

- To raise the Bridge’s profile and solicit initial funding

- To progress the refurbishment of some working parts

- To gain information about the condition of some working parts

Conservation Policy

The Bridge is listed Grade 2* and is on English Heritage’s Buildings at Risk Register.The main structure is constructed of traditional wrought iron, a soft, ductile, fibrous, hand-made material that has not been manufactured for over half a century. As far as is known, no genuine wrought iron is made anywhere in the world, so as wrought ironwork rusts away or is scrapped the extant quantity of the material is gradually diminishing, which adds to its historic importance. As much original material as possible will therefore be retained, areas weakened by corrosion being repaired by welding in new pieces of material. Where larger sections are needed, these will be riveted in place using hot-set rivets. Trial repairs using both these processes have recently been carried out successfully.

The aim of the project is to restore the Bridge to working condition for occasional use under Bristol City Docks Harbour Master's control as a crossing for pedestrians and cyclists over the Entrance Lock. In accordance with good conservation practise, as much extant historic material as possible will be retained, repair being preferable to renewal.The Bridge will be treated as an historic monument and returned to its original 1849 appearance without improvement or upgrading to CE standards. This approach is fully supported by Historic England The Mayor and the Docks operational staff.

The construction and condition of the Bridge have been investigated in detail over the last three years, and a detailed costed programme of repairs has been prepared. These are set out in a report dated August 2015 by conservation-accredited engineers Mann-Williams.

The Project will be delivered by the Avon Industrial Building Trust, a well-established body that has carried out many successful conservation projects in the Bristol area, including the restoration of Midford Aqueduct, a project of similar value to the Brunel Swivel Bridge but greater complexity. The Swivel Bridge Technical team comprises professionals from structural, bridge and marine engineering, an engineering historian and a consultant metalwork conservator. The team, working with the Avon Industrial Buildings Trustees, are confident of delivering a high-quality, fully restored Bridge within budget. The estimated restoration lead-time is one year from receipt of funding.

The Whole Plan

The plan for BoB covers fund raising in addition to a detailed assessment of the bridge’s structural condition using a three stage approach:- Stage 1: 2013/14 Surveys, Investigations and Trials

- Stage 2: 2015 Continue to publicise BoB by building public awareness and seeking funding to aid volunteer work and prepare a bid to the HLF.

2015 Volunteers, supported by contractors if necessary, to make repairs to certain mechanical items

- Stage 3: 2016/17 Earliest target for restoration to working condition – providing a bid to HLF for circa £1M is successful.

This work continued in 2015 and 2016 but the major emphasis will be on fund raising. The BoB website (www.brunelsotherbridge.org.uk ) already includes facilities to make donations but wider publicity is needed.

Leaflet

Swivel Bridge Leaflet. Leaflet gives information, asks for support and how to make a donation |

Donations

PLEASE HELP US SAVE BRUNEL’s OTHER BRIDGE. WE HAVE GIVEN UP OUR TIME WILLINGLY TO SAVE THIS FORGOTTEN GRADE II* LISTED BRIDGE. PLEASE HELP US BY PROVIDING DONATIONS LARGE OR SMALL.EVERY LITTLE HELPS. AND PLEASE SPREAD THE WORD AROUND TOO.

You can send a cheque payable to

Avon Industrial Buildings Trust to:

The Treasurer,

24, The Bluebells, Bradley Stoke, Bristol BS32 8BE

Bank details for bank transfer:

Account name: Avon Industrial Buildings Trust

Account address: CAFCASH LTD

Kings Hill

West Malling

Kent ME19 4TA

Sort code: 40-52-40

Account number: 00006720

Progress to date

The structure is severely weakened by rust holes the size of footballs and has not been painted for decades. It continues to rust away and will eventually collapse, which may herald the end of this iconic structure.In August 2013 volunteers carefully chiselled away the rust on the ends of the four main beams that support the 68 Tonne weight of the Bridge deck.

To our horror bucketfulls of rust fell out leaving large holes in key structure. Even the repair plates welded in to strengthen the structure have thinned dramatically and rusted away completely in many places.

Closer inspection reveals extensive loss of metal in these critical areas, making major intervention vital before the structure becomes too weak to move.

For the last three years, dedicated volunteers including many professional engineers have been thoroughly investigating all aspects of the bridge to work out exactly what needs doing to it, and get a good grasp of how much it will cost.

We believe the Avon Industrial Buildings Trust is the only organisation with the ability and will to develop a scheme in the timescale needed to save Brunel’s Swivel Bridge.

This project has been supported by Clifton and Hotwells Improvement Society for many years.

From 2013 Bristol Industrial Archaeological Society, Avon Industrial Buildings Trust and the Hotwells and Cliftonwood Society came to help as well and do some dirty work. The initial refurbishment project is being led by Geoff Wallis of Dorothea Restorations (gwconservation@gmail.com).

Brunel Swivel Bridge, 1876 replica in foreground |

Brunel Swivel Bridge under the Cumberland Basin |

in original position by Entrance Lock not a lot of clearance under the Plimsoll Bridge |

wheel |

CONTRACT WORK undertaken up to March 2016:

- Trial dry-ice and abrasive grit blast-cleaning.

- Trial cutting out and welding in two patch-repair plates.

- Trial removal of rivets and hot-setting new rivets to match.

- CCTV drain survey.

- Removal of one hydraulic ram, dismantling, inspection and refitting in its pit.

- KGAL design for method of centring and driving round the deck-structure, provision of costings.

- Geocon Ltd ground investigations.

- Hole cut in top-tube end-plates to allow internal investigations.

- Removal of all 20th century patch-plates, measurement of local plate-thickness.

- Preparation of outline schedule of work and costings.

Work PHASE B 2015 Preparation and Basic Conservation by Volunteers

- Removing some patch-repair plates to allow us to clean & inspect the inside of enclosed sections. We have agreed to carry out a permanent repair now as follows to the investigative test section. This will be done by Dorothea Restorations

- Erecting a simple timber roof

- renewal of the timber stop.

- Moving the timber and erecting our two new interpretation panels (Feb/March). Timber already moved.

- More Cleaning and painting rusty areas

- Unbolt and release the centre pintle casting

- Jack up Bridge further

- Level and Dimensional Survey.

- Metalwork condition survey using Ultrasonic equipment from DMV

- Kentledge Weight Survey

- Paint Analysis

- Site Investigation, Excavating a hole adjacent the CI bed, SE side to search for a timber foundation-beam

- Locate and obtain copies of drawings and past reports. Write a conservation plan

- Seek letters of support

Work 2014 Preparation and Basic Conservation by Volunteers

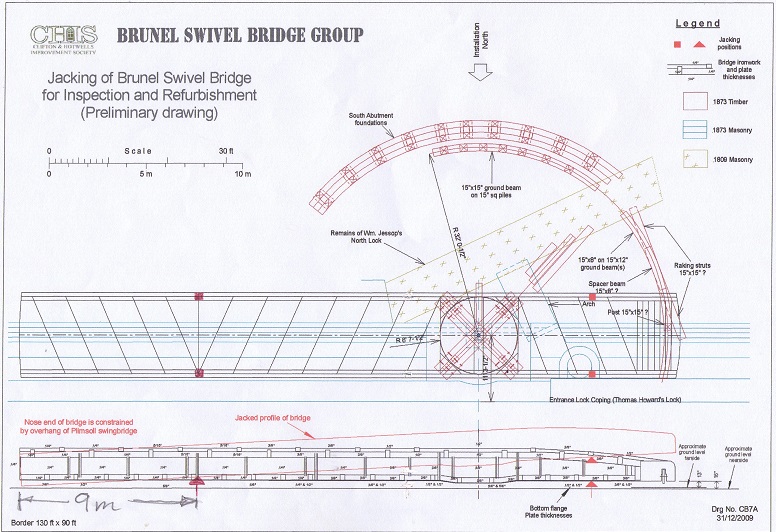

Jacking Method

We bought two 50 ton jacks in February 2014 to lift the bridge for easier access

- Cleaning and painting rusty areas

- Unbolt and release the centre pintle casting

- Jack up Bridge a few inches

- Free up north tail wheel

- Release two rotation cables

- Lower bridge onto its pintle and track

- Free the pintle thread, rotate bridge a small amount and return to present position

- Locate and obtain copies of drawings and past reports. Write a conservation plan

- Seek letters of support

Work PHASE A 2013 Preparation and Basic Conservation by Volunteers

- Locate and obtain copies of drawings and past reports. Write a conservation plan (in progress)

- Seek letters of support

- Provide temporary barriers at both ends of the structure to prevent access between the Bridge and basin

- Lay temporary boarding along the west end of the deck to provide access

- Clear debris, vegetation, etc, from around and under the Bridge, and in the hydraulic jigger-pits. Dispose off site (largely completed)

- Scrape/chip off loose rust, apply temporary coating of rust inhibitor (testing paint)

- Free-off the shackle-pins on the steel rope and remove if accessible

- Provide a 2 inch (51mm) spanner/socket, free off and remove 8 pairs of nuts securing the four support-wheel bearing caps. Lift off caps, clean, inspect, record, lubricate and reassemble (done)

- Provide a spanner/socket, free off and remove 4 pairs of nuts securing the two tail wheel bearing caps. Support the wheels, lift off the caps, clean, inspect, record, lubricate and reassemble (done)

- Remove deck boards to store on site, and dispose of rubbish, leave the site tidy (filled a skip)

Brunel's Other Bridge

Brunel's Other Bridge